316 is a popular grade of stainless steel composed of 16-18% chromium, 2-3% molybdenum, 10-14% nickel, and a small percentage of carbon. These tubes have high wear and tear resistance, and optimum strength. The addition of molybdenum increases their corrosion resistance compared to other grades. A 316 seamless tube has slightly different properties than 316 tubes, having higher strength and incredible corrosion resistance, including in extremely corrosive and marine environments. However, it is less malleable and machinable than 304 stainless steel.

It is mostly used in aerospace, industrial, natural gas, oil and petroleum, food and beverage, architectural, cryogenic, and marine applications. These tubes are available in full-size or custom-cut lengths. A 316 seamless tube can easily maintain its properties even in cryogenic or high temperatures. It also has a high wear and tear resistance. Many manufacturers and suppliers of 316 seamless pipes provide these tubes in different types and specifications to meet the buyer’s demands. It finds its applications in the food processing industry, seawater processing plants, heat exchangers and boilers, nuclear power plants, etc., due to its chloride ion corrosion stress cracking resistance, enabling it to survive in chloride ion-rich environments.

Seamless 316 tubes also can withstand high temperatures, which is why they are used for high-temperature applications. You can find different specifications of these tubes and also different sizes. Many manufacturers offer products of high quality and standards. Since many industries demand seamless 316 stainless steel tubes, they are designed for standard quality of international and national raw materials. Seamless tubes have nickel and molybdenum in their composition, strengthening the product quality.

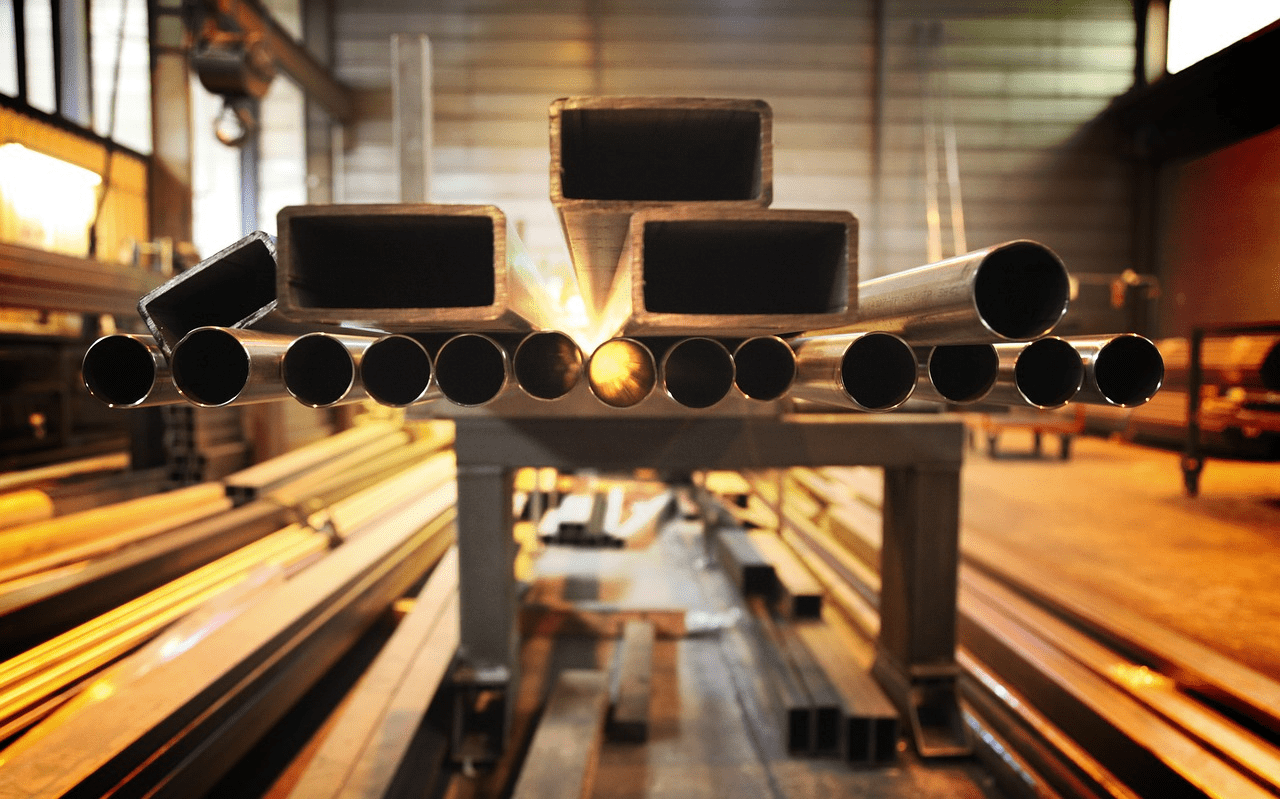

Some important features of seamless 316 tubes include high tensile strength, good dimensional accuracy, machinability, resistance to pitting/ stress/ cracking/ crevice corrosion, good weldability and formability, and anti-corrosive nature. These seamless tubes are also produced in various shapes: square, rectangle, round, coil, U-shape, hydraulic, and honed.

This category of tubes is considered hygienic and sanitary since they are extremely cleanable. The cleaning can be performed simply by dismantling the tubing systems followed by manual cleaning, or a clean-in-place (CIP) process can be used. Another reason they are considered sanitary is that they limit entrapment areas for bacteria. These sanitary tubes are also corrosion-resistant. Hence, this makes them extremely useful in the pharmaceutical and food and beverage industry since they require hygiene and non-toxic end-products.

Also, the seamless 316 tubes are produced per certain guidelines, requiring them to be checked for mechanical properties like yield and tensile strength, hardness and elongation. The textile industry also uses seamless 316 tubes. The processes involved in this industry use cotton or linen fibres that are sourced and bleached to remove impurities, using various salts and soaps or chemical solutions. This makes them highly susceptible to corrosion. 316 stainless steel tubes offer a great option for such applications. They are also suitable for the various dyeing techniques that use different chemicals. 316 offers good resistance to phosphoric and acetic acid in the dyeing process.

Summing Up

Seamless 316 tubes play a major role in most industries, as discussed above. Their excellent properties make them one of the most popular grades of stainless steel tubes in many applications.