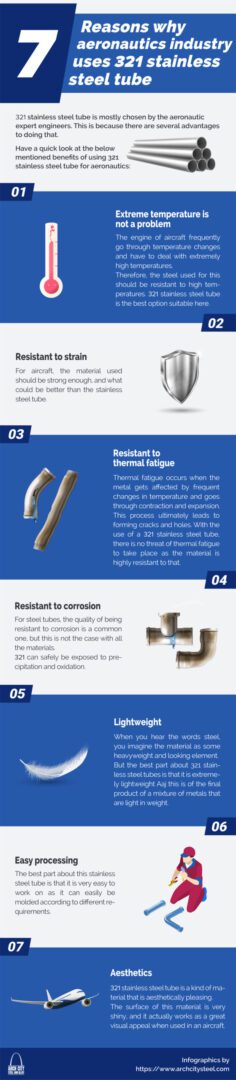

Aeronautic expert engineers prefer 321 stainless steel tubes for use in different parts of the aircraft. Aircraft engines have to deal with extreme temperature changes as high as 1500 degrees Fahrenheit. 321 is a solid alloy that can be used at such temperatures. It can also be used at low temperatures without affecting the aircraft’s performance or reducing its life span.

Aircraft operate under high pressure, which severely tests their tensile strength. This needs that the materials used in specific areas should be strong, so stainless steel tube is the far better option. When dealing with 321 stainless steel tube, engineers can be sure that they will not find signs of fatigue as this alloy can withstand different temperatures and remain free from cracks. Corrosion-resistant is another quality of stainless steel; 321 is ideal for use in critical areas of an aircraft exposed to the elements.