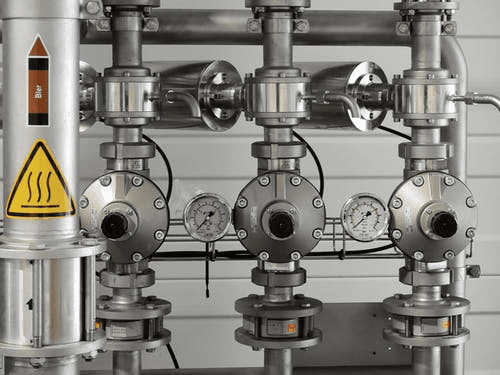

Are you deployed as a senior supervisor or in similar roles in an oil or gas plant? Then you must have to screen various parts, products, and equipment regularly to ensure uninterrupted workflow. However, sometimes even after performing regular checks, some parts of the transmission channel fail. Thus, the need to purchase 304 stainless steel tube is not new when the pipes carrying your oil or gas leak or develop other issues. In that case, you must find a quality-centric vendor of stainless-steel materials that can provide you with original pipes and tubes with guaranteed durability. Continue reading “Top 4 Applications of 304 Stainless Steel in the Oil and Gas Industry You Must Know about”