In precision engineering, the choice of material can define both safety and performance. Among alloy steels, 4130 tubing has earned a reputation for its strength, workability, and consistency under pressure. It is widely used in automotive frames, aircraft parts, and high-stress structural applications.

4130 gets its name from the elements it contains, chromium and molybdenum, which enhance its hardness and resistance to wear. It performs well under heat treatment and is easy to weld, making it ideal for complex builds that require long-term durability. Engineers favor it when structural integrity cannot be compromised.

When selecting high-performance materials, 4130 tubing stands out for balancing tensile strength with adaptability. Whether you’re designing lightweight roll cages or critical aerospace components, it’s a go-to choice for professionals who prioritize both performance and precision.

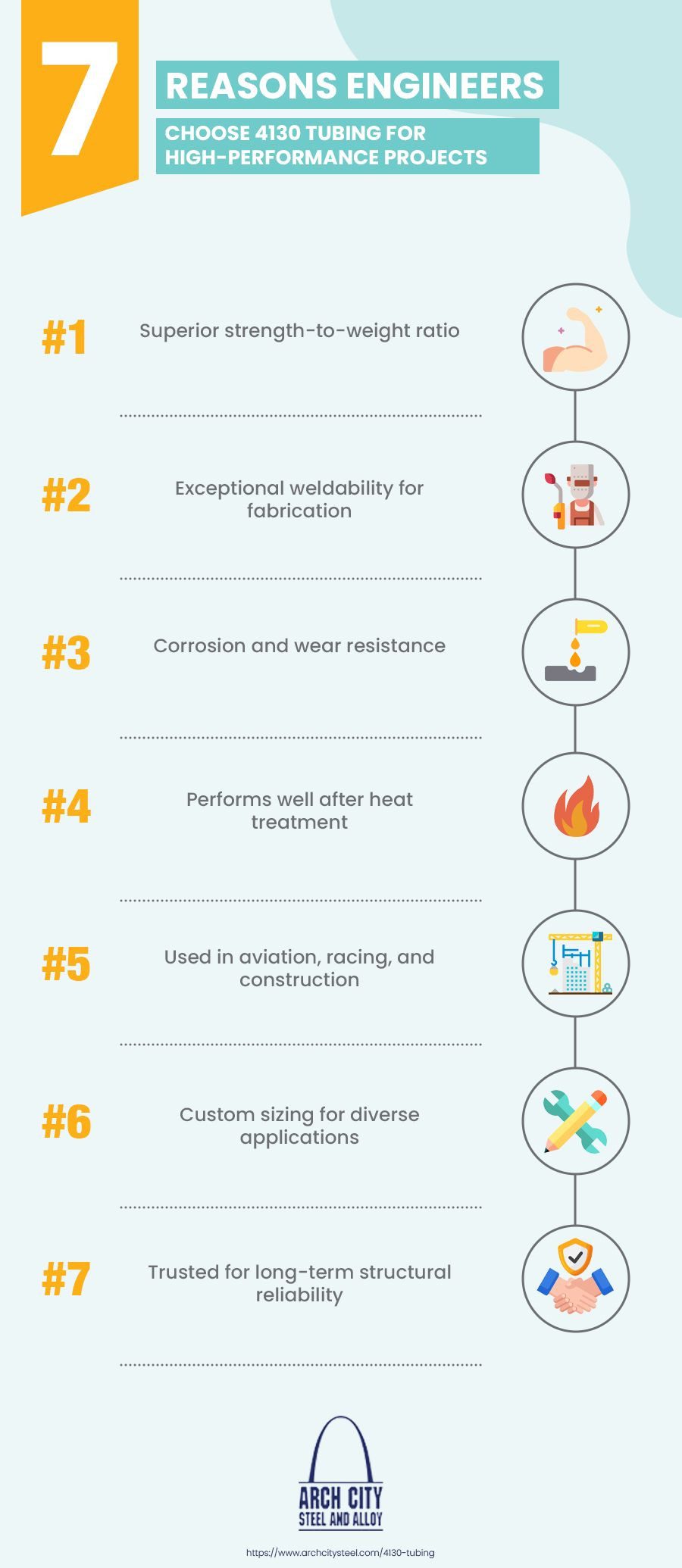

Here is an infographic showing 7 Reasons Engineers Choose 4130 Tubing for High-Performance Projects.