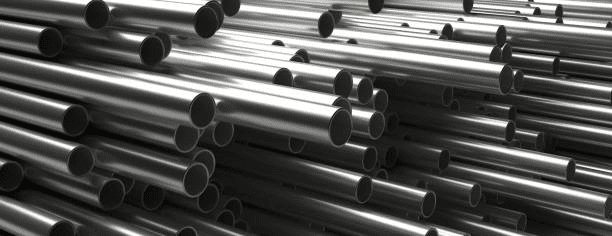

Stainless steel 317L is a type of metal known for its excellent resistance to corrosion, which makes it a great choice for various industrial uses. Picking the right grade and specifications of 317L stainless steel can be crucial for your project’s success and durability. Here’s a simple guide to help you choose the right stainless steel 317L. Continue reading “How to Select the Right Stainless Steel 317L for Your Needs”