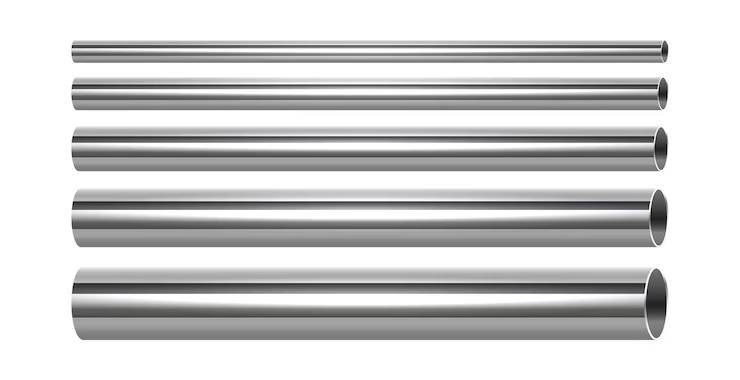

Industrial projects demand the use of materials that deliver consistent performance under harsh conditions. Engineers face mounting pressure to select components like 321 stainless steel tubes that minimize downtime while maximizing operational lifespan. When critical systems fail due to material degradation, the costs spiral beyond initial replacement expenses. Continue reading “Top 5 Benefits of 321 Stainless Steel Tubes for different Industries”