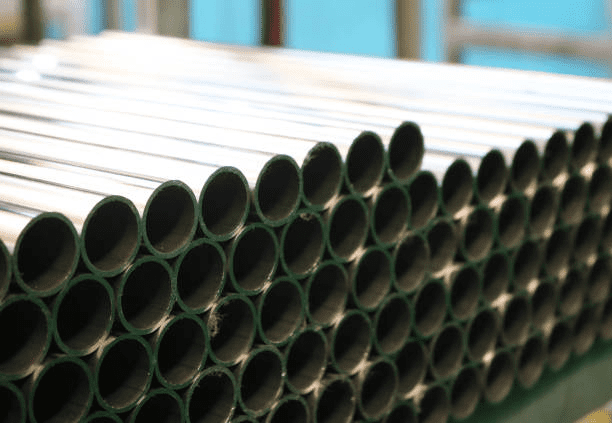

Industrial operations in harsh environments demand the use of materials that perform predictably over extended service periods without unexpected failures or costly downtime. Nickel alloy 201 tubing stands out in applications where corrosion resistance and mechanical stability directly impact operational continuity. This material choice reduces total cost of ownership through fewer replacements and minimal maintenance interventions.

Continue reading “Applications Where Nickel Alloy 201 Tubing Delivers Long-Term Reliability”