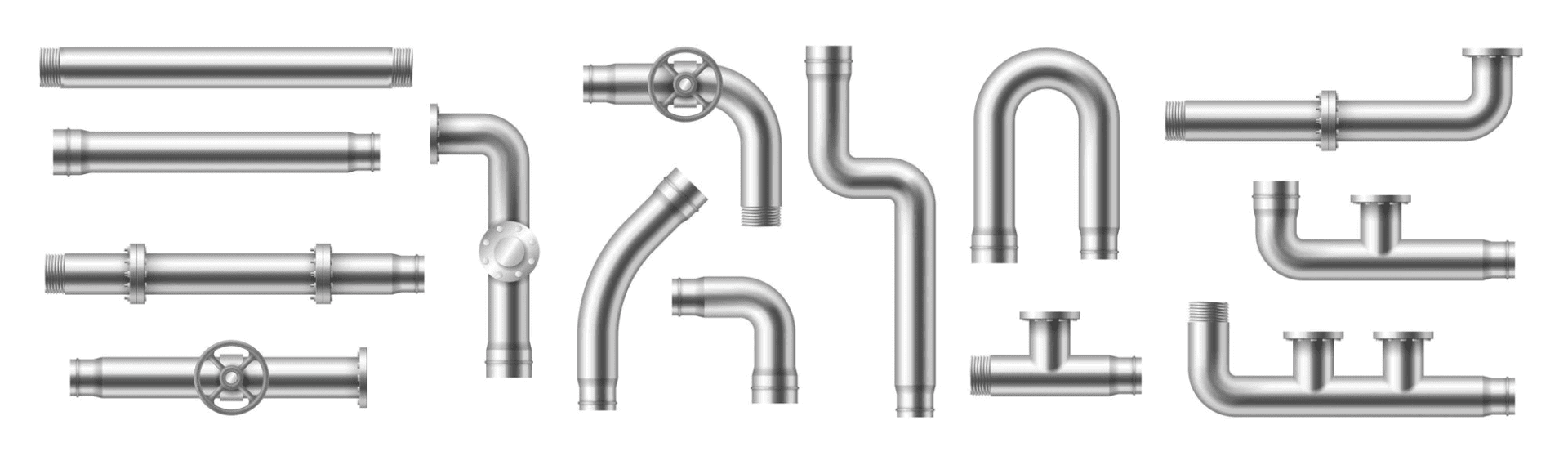

Heavy wall stainless steel tubing stands out as an important material for demanding environments. Its exceptional strength, durability, and resilience make it a preferred choice in industries that require materials capable of withstanding extreme pressures and harsh conditions. From high-temperature applications to corrosive environments, this tubing delivers amazing reliability and long-term performance. Continue reading “7 Must-Know Benefits of Heavy Wall Stainless Steel Tubing [Infographic]”