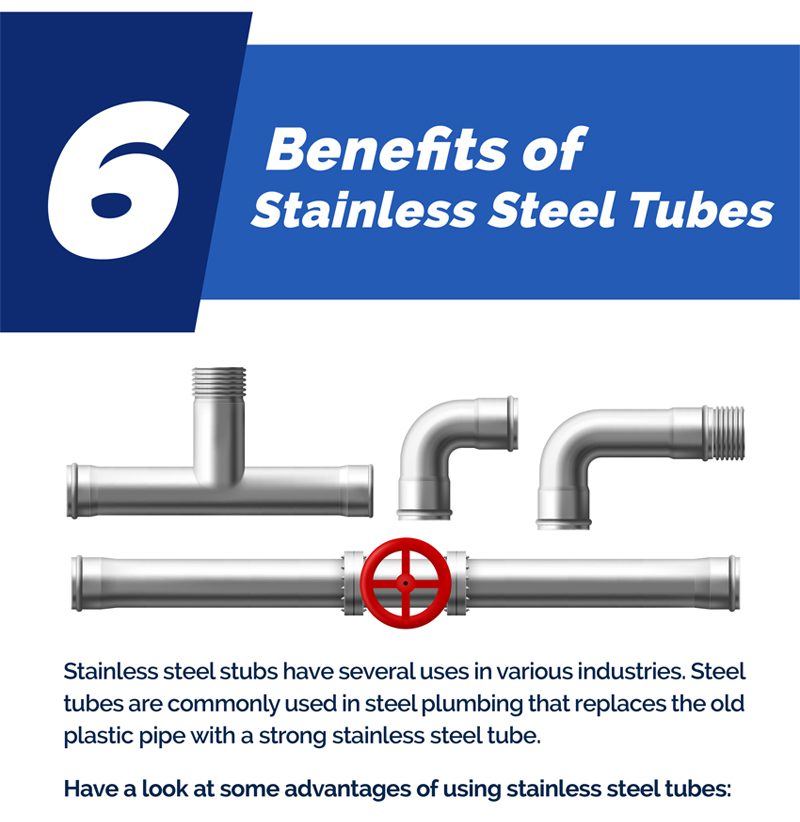

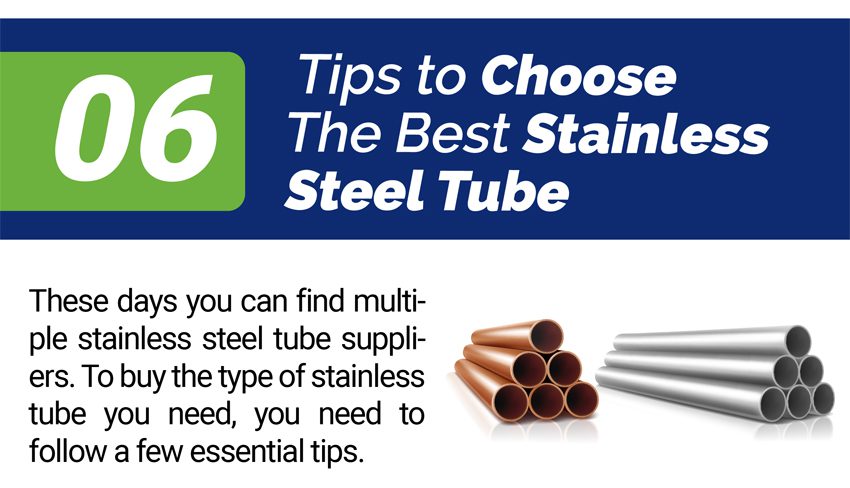

There are many factors you should consider when selecting stainless steel tube. The main requirement for stainless steels is that it should be corrosion resistant for a specified application or environment. Strength and fabrication characteristics are also taken into consideration. Make sure the material used to make the stainless steel tube is safe to use at various temperatures. Continue reading “Infographic: 06 Tips To Choose The Best Stainless Steel Tube”