Nickel is a metal used independently and together with stainless steel. Here is all you need to know about nickel used in the manufacture of stainless steel.

Nickel was first identified in the 1700s and it was then referred to as ‘kupfernickel’ since it was found in copper ore. When they saw it for the first time, they did not know that the element giving them difficulties in extracting copper was a nickel. They did not know that nickel would emerge as a great metal beneficial for industries. Nickel alloy 20 tubing is used to make stainless steel that is resistant to corrosion. So why is nickel important in the manufacture of stainless steel? Here are some of the things you need to know about the use of steel in the industry.

Increasing the Toughness of Steel

When chromium is added to steel, the steel metal toughness will decrease. Nickel is added to the steel as a compensation for the decreasing toughness of the steel metal.

Ferromagnetism

When chromium is added to steel, it will induce ferromagnetism which hinders the working of a number of applications. Nickel is added to steel to counter the issue.

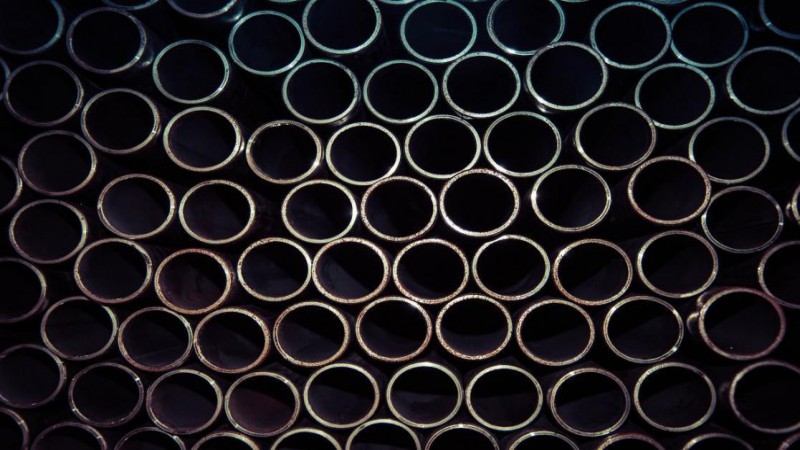

From the above illustration, we can easily comprehend that nickel makes the stainless steel to have its stainless ability. It is used to enhance its resistance to corrosion at high temperatures. The alloys made using nickel are used in the manufacture of tubing products. The main reason why they are used in the manufacture of the tubing products is the resistance to corrosion at high temperatures.

Since they are resistant to oxidation and corrosion and have high boiling points they are also ductile. It is so easy to electroplate them and weld them. They are appropriate for use in the high and low-temperature industries.

A Wide Range of Applications

The nickel can also easily accept the alloy elements in the form of a solid solution as compared to steel or iron alloys. This also means that they have the ability to maintain a high metallurgical ability. A combination of the multiple elements will provide high corrosion in different environments while at the same time making sure that it has great welding characteristics.

The alloys are also used in the manufacture of heat exchangers in the nuclear and the processing industry. They are placed in steam generators, used in nuclear power and the gas extraction process. Due to their corrosion, they are used in making desalination equipment.

The high degree of corrosion of nickel is due to its position in the series of metals. When you add chromium, copper and many other elements to nickel, the resistance of the metal to corrosion will increase making it possible for its use in many industrial applications.

Nickel is a great element used in making nickel alloy 20 tubing. Due to its increased popularity in the manufacture of stainless steel, nickel is also used in the manufacture of many other industrial applications. These applications are used to run a number of activities within the industry.