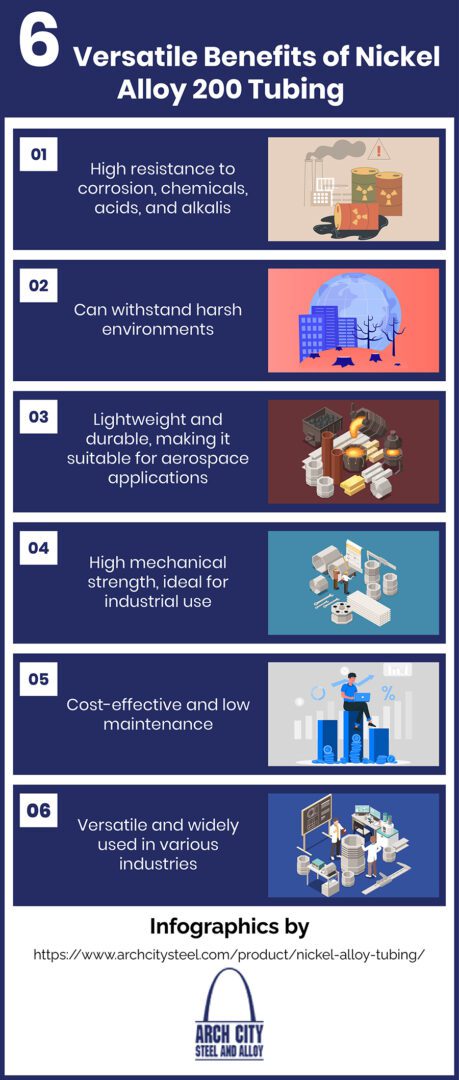

Nickel alloy 200 tubing has become increasingly popular in various industries due to its exceptional properties and versatility. This material is a pure form of nickel and is commonly used in applications that require high corrosion resistance and excellent mechanical strength.

One of the primary reasons for the popularity of Nickel alloy 200 tubing is its ability to withstand extreme temperatures and harsh environments. It can resist corrosion caused by chemicals, acids, and alkalis, making it a popular choice for chemical processing and oil and gas applications.

Nickel alloy 200 tubing is also widely used in the aerospace industry due to its lightweight and durable nature. It is commonly used for manufacturing aircraft parts and components that require high strength and excellent resistance to heat and corrosion.

In addition to its excellent mechanical properties, Nickel alloy 200 tubings are a cost-effective solution for many applications. Its long-lasting durability and low maintenance requirements make it an ideal material for industrial use.

The popularity of Nickel alloy 200 tubing is due to its exceptional performance and versatility in various applications. Its unique properties have made it a preferred material for industries such as chemical processing, oil and gas, aerospace, and many more.