In industries where speed, strength, and precision define success, materials must meet the highest performance standards. From aircraft to race cars, the structural components used must be light yet incredibly strong, and that’s where 4130 tubing comes into play.

4130 tubing, an alloy steel that includes chromium and molybdenum, is revered for its exceptional strength-to-weight ratio and high fatigue resistance. These properties make it a staple in environments that demand both performance and safety.

Because of its weldability, corrosion resistance, and ability to retain strength under heat, this alloy is widely used in aerospace frames, roll cages, and performance vehicle chassis. It’s not just a material. It’s the backbone of modern high-performance engineering.

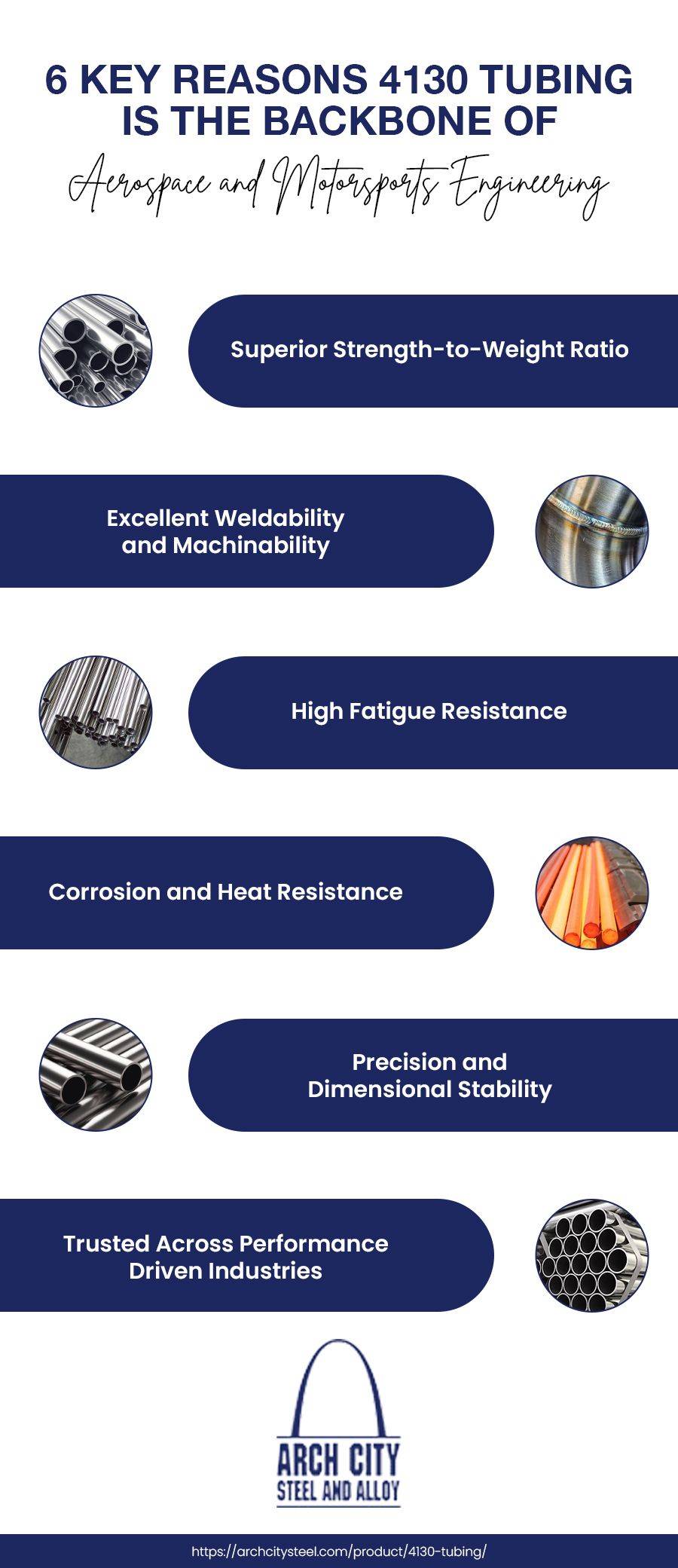

Here’s an infographic showing 6 Key Reasons 4130 Tubing is the Backbone of Aerospace and Motorsports Engineering