Known for its exceptional combination of strength, toughness, and machinability, 4130 rectangular tubing is a trusted choice across aerospace, automotive, and structural engineering industries. This alloy, composed mainly of chromium and molybdenum, offers a unique balance of durability and light weight that makes it suitable for high-stress environments where precision and performance are critical.

Beyond its strength, what truly sets 4130 tubing apart is its adaptability. Engineers can manipulate its hardness and toughness through heat treatment while maintaining weld integrity and structural consistency. This flexibility allows it to be used in diverse fabrication projects ranging from aircraft components to performance car frames and heavy machinery frameworks.

Its corrosion resistance, ease of welding, and fatigue endurance also make it a favorite for both manufacturing and repair applications. Whether used in roll cages or hydraulic structures, 4130 rectangular tubing ensures long-lasting performance under pressure. Below are seven engineering facts that showcase why this alloy remains an essential material in modern fabrication and design.

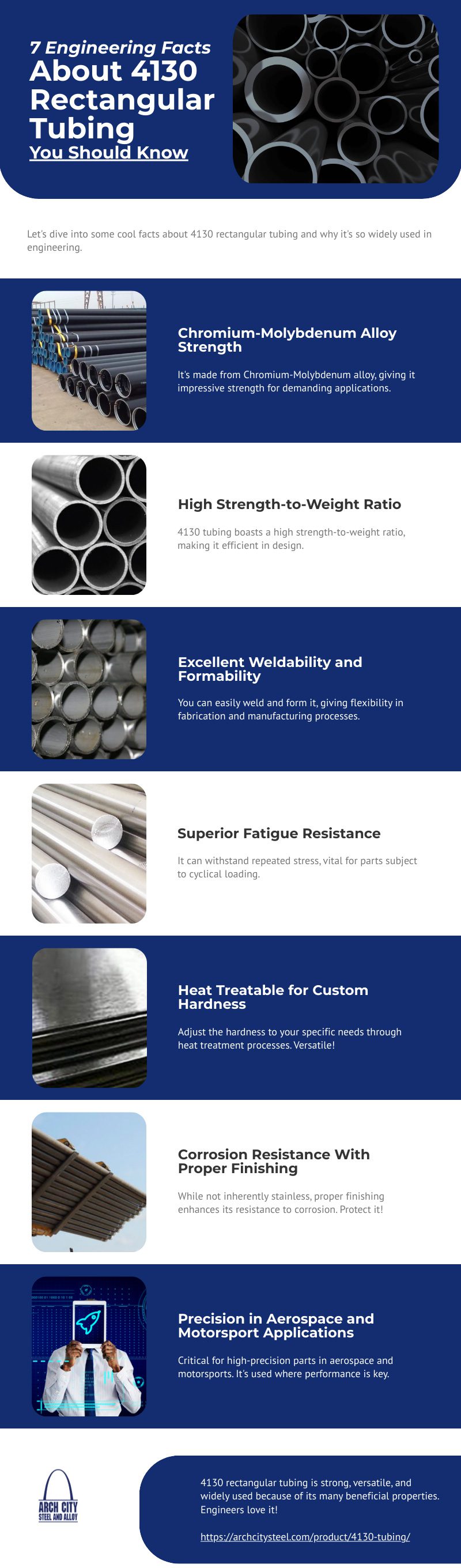

Here is an infographic showing 7 engineering facts about 4130 rectangular tubing you should know.